ASF Virus

The World Organisation for Animal Health currently lists many countries, especially in Europe and Asia, being affected by the African swine fever epidemic.

The ASF virus affects domestic and wild pigs, with a mortality rate of up to 100%. The disease and its consequences are the cause of serious socio-economic problems in livestock breeding.

African swine fever virus is a double-stranded DNA virus belonging to the unique species African Swine Fever Virus ASFv the genus Asfivirus and the family Asfarviridae. However, there are several different genotypes and virulences which are more or less severe depending on the strains. This virus is relatively large compared to others and has a more complex structure with the presence of an outer lipid envelope. In the fight against this disease, this is an advantage as it is therefore much more sensitive to disinfectants that inactivate it more easily than viruses without an envelope (known as naked), which is especially true if they are small.

Multiple Ways the Disease Can Be Transmitted to Pigs

Direct Contact – Indirect Contact – Ingestion – Insect Bite

According to different sources, the routes of transmission are as follows:

– by contact to contaminated live or dead pigs

– by contact to contaminated vehicles, shoes, clothes and equipment

– by ingestion of contaminated water or food

– by air over short distances or

– by some insect bites.

Dissemination of the Virus

in the Environment

Fast – Large – Durable

The virus is relatively resistant in the environment and therefore it can spread very quickly. Some strains can remain infectious across a wide range of pH, from pH4 to pH13.

Studies also show still virulent activity in strains stored for 5 and 7 years at 5°C, 18 months at room temperature and between 10 and 30 days at 37°C. The virus can also survive in protective media such as soil or animal feces for 5 to 6 months and up to 30 months in chilled meat. However, it is inactivated at a temperature of 60°C applied for 30 minutes.

How to Prevent it

Protection of animals from possible sources of the virus

The prevention of transmission is a mix of biosecurity measures, a combination of active hygiene management alongside structural management.

A complete hygiene program incorporates the three pillars ‘‘Cleaning, Disinfection and Protection’’. While cleaning and disinfection with the right product applied correctly at the required concentration ensure a clean shed when new animals arrive, protection ensures that no harmful pathogens will enter the shed by means of hygiene and structural management while animals are present. Only this mix will ensure healthy animals and a prosperous farm.

Effective cleaning of surfaces and equipment ensures the best possible condition for disinfection.

Successful disinfection is the elimination of micro-organisms through the selection of a proven disinfectant, applied at the correct dilution rate with adequate contact time.

Comprehensive Biosecurity measures are required to prevent micro-organisms from re-entering and contaminating clean buildings and equipment.

Avoidance is Better Than Cure!

General biosecurity measures

Preventive Cleaning, Disinfection and Protection Measures

On farms, ensure the protection of the animals with regards to all the external sources and entrants:

- Control of access to buildings (visitors, staff…): use of personal protective equipment to access livestock buildings – Cleaning and Disinfection procedures.

- Limiting the arrival of external vehicles on site including those used for the transport of animals. Apply Cleaning and Disinfection procedures for vehicles in any case.

- Improvement of building maintenance, pest control, rodent control, liquid manure removal…

- Improvement of Cleaning and Disinfection procedures on all surfaces of buildings and equipment and the environment in general.

- Monitoring of entrants (food, water…),

- Monitoring animal health (abnormal signs or symptoms…)

If the disease is reported

Confinement – Isolation – Crisis Management

If a case is proven, the establishment of a management procedure for hazardous areas including

- Elimination of animals: the slaughter of all animals in the premises concerned.

- Isolation and securing of the site: rigorous and controlled confinement and isolation procedures.

- Cleaning and disinfection of premises in collaboration with the competent authorities and selected service providers

ASF – Active Management

Cleaning, Disinfection & Protection –

Step-by-Step

1. Cleaning

- Product selection, concentration and application is key to successful cleaning.

- Effective cleaning of surfaces and equipment ensures the best possible condition for disinfection.

2. Disinfection

- Product selection, concentration and application is key to successful disinfection.

- Successful disinfection is the elimination of micro-organisms through the selection of a proven disinfectant, applied at the correct dilution rate with adequate contact time.

3. Protection - by means of hygiene management

- Product selection, concentration and application is key to successful protection.

- Offer possibilities and make it obligatory to disinfect boots, wheels, vehicles, hands and equipment prior to and after entering the premises or different areas of the premises.

- Cleaning and disinfection of the water system & water disinfection

4. Protection - by means of structural management

Implement additional measures to prevent ASF from entering your building:

- Protection against uncontrolled movement and entering (people, vehicles, wild animals) – i.e. fences are intact, lockable gates, etc.

- Limitation of passenger and vehicle traffic to the necessary minimum, keeping a visitor’s book

- Consistent implementation of the “CLEAN and DIRTY zones” principle:

- Enter the premises only with company clothing and prior showering

-

- Street clothing and stable protective clothing are kept separate from each other before and after entering the production areas

- Division of the business premises into “CLEAN” (animals, feed, bedding etc.) and “DIRTY” (manure, carcasses etc.) areas

- Avoid crossing paths, from “DIRTY” and “CLEAN” areas

- Storage of the carcass in a closed container or similar construction, which is secured against unauthorized access and the entry of vermin, rodents, wild animals and the leakage of liquids and which is easy to clean and disinfect

- Relocation of carcasses as close to the road as possible on paved ground that is easy to clean and disinfect, so that the vehicle of the processing plant for animal by-products does not have to drive on the premises

Feed and litter deliveries, as well as loading or unloading of breeding and slaughter pigs, only take place on the traffic areas (no traffic and access by outside persons in the production areas)

- Feed, bedding & other resources are stored safely protected from wild boar

- Special employee training on the ASP transmission risks, in particular, the ban on bringing sausage products into the company and private pig farming

- Continuous Pest control including documentation

- Continuous animal health monitoring (abnormal signs or symptoms…)

Proven ASF Case

If an ASF case is proven, a management procedure for hazardous areas include:

- Elimination of animals: the slaughter of all animals in the premises concerned.

- Isolation and securing of the site: rigorous and controlled confinement and isolation procedures.

- Cleaning and disinfection of premises in collaboration with the competent authorities and selected service providers

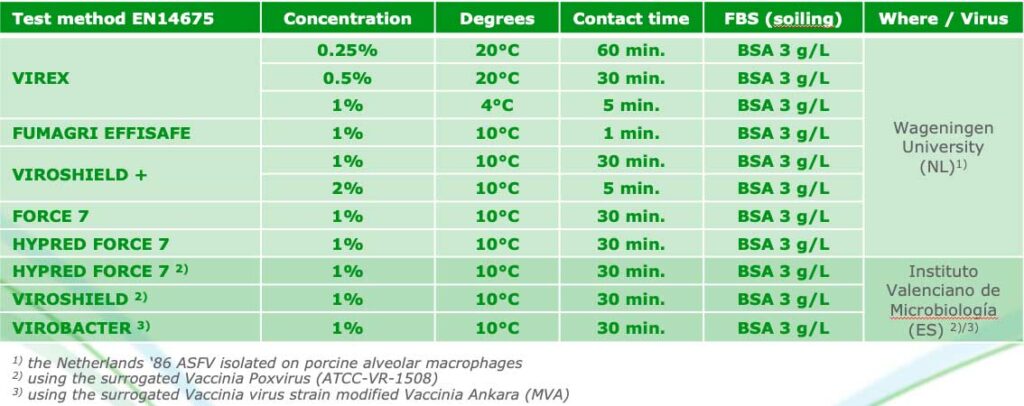

Kersia Solutions Against ASF