Kersia, leader in hygiene solutions, has a complete offer of disinfectants, detergents, lubricants, water treatment solutions etc. adapted specifically to the needs of the brewery and the beverage industry. Kersia products meet the highest performance, eco-responsibility and cost standards.

Kersia’s cleaning and sanitizing programs thus ensure the quality and safety of your beverages, while improving operational efficiency.

BEERS AND CIDERS

Kersia strengthens its leadership of the brewery segment

With the acquisition of Sopura, an internationally recognized expert in the brewing industry with more than 70 years of experience in over 100 countries worldwide, Kersia is now “the” reference in this sector, providing complete cleaning and disinfecting solutions from the brew house to the bottling hall.

Each brewery is a unique case, depending on the type and size of the brewery. The Kersia Group’s experts offer solutions adapted to each constraint of your different industrial processes.

PROCESSING WATER TREATMENT

Our water treatment experts optimize the quality of the water supplied to the different steps of the production process.

Program for each step of the brewing process

Kersia offers a complete and customized cleaning and sanitizing solution specially designed to protect beer quality while improving operational efficiency and sustainability. Measures that offer the brewer real added value.

Open Plant Cleaning

Kersia offers products, application equipment and cleaning and sanitizing procedures for Open Plant Cleaning (OPC) of all types of equipment and production surfaces.

.

Treatment of pasteurizers

Kersia proposes various technologies and products to treat pasteurizers against biofilm formation, corrosion and scaling with custom solutions for specific local situations.

CIP dedicated to the brew house

CIP dedicated to the brew house

Kersia offers overall approach solutions with CIP dedicated to the brew house (hot block) and specific solutions for certain process applications.

Cleaning & sanitizing filters

The way of filtering, blending and clarifying determines the stability of the flavour and the quality of the beer. Kersia has designed the top-performing concepts (products and processes) to clean and sanitize the different types of filters.

Bottle washing

Specific chemistry is available to clean (heavily soiled) bottles and to remove labels and glue residues. Masking heavily scuffed bottles and prevention of glass corrosion, allows a new branding of your bottle without high CAPEX investments.

.

Fermentation block

During fermentation, organic and inorganic deposits form and may alter the quality of your product. Kersia has developped great expertise in cleaning and sanitizing fermentation and storage tanks, annexes and pipes.

Cleaning & sanitizing of BBT

The single-phase cleaning process of BBT (Beer Bright Tank) provides savings in water, energy and time. We recommend the segregation of CIP for filtered and unfiltered beer.

.

WINE, SPIRITS AND RTDs

We’ve worked with the wine industry for many years. We have built our expertise on the everyday challenges met by winemakers, respecting both the product and the local, national and international regulations.

Our experts have developed specific cleaning and disinfecting programs for the grape reception and pressing equipment. If sanitation usually takes place before the beginning and at the end of the harvest campaign, week-end disinfection programs can be required. It benefits from especially engineered solutions. Scaling on fermentation tanks is fought with combination of detartrating products. Wine stains on porous floors are often difficult to be removed but for the Sopura specific combination of cleaning products. Cleaning and disinfecting programs for filters and bottle fillers present the ideal combination of products, equipment and time for cost efficient sanitation.

SOFT DRINKS, JUICES, BOTTLED WATER

As a manufacturer or bottler of carbonated or non-carbonated soft drinks, your production process needs to be up to date with the highest quality level as possible.

Kersia delivers tailor-made solutions for your specific production process, offering the best matching CIP regimes for your specific conditions.

Whether your products are conditioned in returnable or non-returnable packaging, we have developed products and solutions to maximize the efficiency, hygiene and quality of your filling lines. We offer specific products as well as engineered solutions for the wet, dry and hybrid lubrication of conveyor systems.

We have various solutions for the manual, semi-automated or automated cleaning and disinfecting of your filling equipment.

THE KERSIA ADDED VALUE TO THE BEVERAGE MARKET

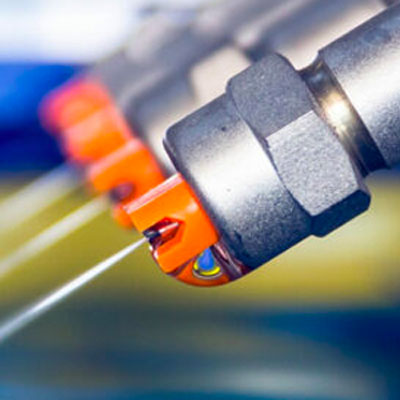

Conveyor lubrication

Lubrication is essential to the speed as well as to the throughput of the filling lines. It also impacts the health and safety of operators, water and energy consumption and effluents quality.

Kersia offers different concepts:

- Optimized wet lube (the most cost-effective wet lube system).

- Hybrid lube (also for stainless steel lines and glass bottles) will save up to 80% of your water consumption compared to wet lubrication.

- True dry lube (plastic conveyors, PET and can lines).

Monophase products

Monophase cleaning requires the use of a high-performance product capable of removing dirt in a single step, thus eliminating the intermediate acid phase and its rinsing.

The single phase approach in brewing industry is a combined acid cleaning and disinfection allowing removal of beerstone and other inorganic residues and removal of organic residues in only one step.

- Saving cleaning products

- Saving time

- Saving water

- Saving energy

Technical support

Our technical experts ensure washing and sanitizing performance, appropriate use of products and compliance with procedures with supporting digital inspection reports.

Depending on your needs and application, we will provide the most suitable products: bottle care products, low amine products range, chemicals with good environmental criteria, personal hygiene etc.