Milk and dairy products have a prominent place in people’s diets, and a positive image as nourishing foods that combine health and pleasure. In Europe and the US, annual consumption of all forms of dairy products (milk and milk drinks, cheese, butter, cream, yoghurt, etc.) exceeds 150 kg per person per year.

However, milk is sensitive to the risk of contamination by microorganism and chemicals residues in the environment. As a result, in many countries the dairy industry is subject to increasingly stringent regulation and evolving market interest on hygiene standards and the chemicals used which may leave residues.

The rapid spread of information on cases of food poisoning or contaminated dairy products has increased consumer mistrust, and it is more important than ever to them that they can consume safe dairy products. It can be costly to issue warnings and then to recall suspect products, both financially and in terms of reputation. Hygiene measures are essential and indisputable, yet consumers also demand products free from residues. This dual desire requires a delicate balance, as overly aggressive hygiene and disinfection solutions or wrongly applied concentrations are avoided to prevent excessive intrusion.

Prevention, a golden rule

Control of the health quality of milk and dairy products begins on the farm and remains an imperative during transport and throughout the various stages of manufacturing for finished products. It is a priority and a constant concern for manufacturers in the dairy industry to prevent risks of contamination by pathogens or chemicals.

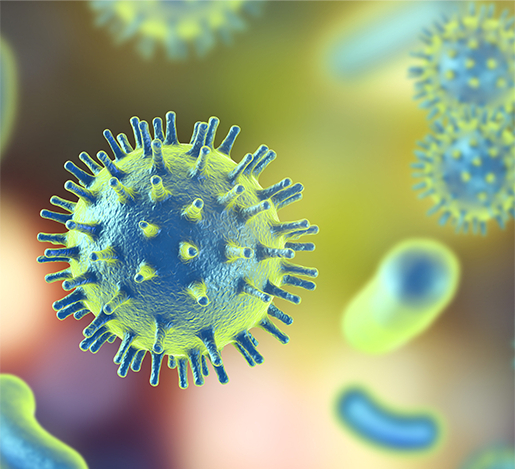

In the dairy industry, various pathogens can potentially contaminate dairy products, posing risks to consumer health.

Here are some of the most important microbiological hazards in dairy products:

Main Occurrence

Main Pathogens in Dairy Processing and its Source, Transmission and Concern 1)

RAW MILK

Escherichia coli (E. coli):

• Source & Transmission: raw milk contamination during milking process (on farm); cross contamination through contact with contaminated surfaces and equipment.

• Concern: Certain strains of E. coli (e.g. E. coli O157:H7) can cause severe foodborne illnesses.

Campylobacter jejuni:

• Source & Transmission: Primary source is theraw milk contamination during milking process (on farm); cross contamination through contact with contaminated surfaces and equipment.

• Concern: gastroenteritis and is a common cause of foodborne illness.

POWDERED INFANT FORMULA

Cronobacter spp.:

• Source: Widely distributed in the environment, including soil, water, production facilities.

• Transmission: Contaminated raw milk; Contaminated equipment, surfaces, or personnel in dairy processing facilities.

• Concern: in infants it can lead to serious health complications, including meningitis, sepsis, and necrotizing enterocolitis, which can be life-threatening.

Salmonella spp.:

• Source / Transmission: Contaminated raw milk is a primary source (on farm), cross-contamination from equipment and surfaces is possible.

• Concern: gastroenteritis & other foodborne illnesses.

SOFT AND SEMISOFT CHEESES

Listeria monocytogenes:

• Source / Transmission: Contaminated raw milk (on farm) , also widely distributed in the environment, including soil and water. Contamination occurs during milk collection, processing, and packaging stages if proper hygiene and sanitation practices are not followed. Cross-contamination from equipment, surfaces, or personnel is possible.

Concern: Can cause listeriosis, which is particularly dangerous for pregnant women, infants, and individuals with weakened immune systems.

Staphylococcus aureus:

• Source/Transmission: Contaminated raw milk; Cross contamination as it can be found on the skin and mucous membranes of humans and animals and on surfaces / equipment.

• Concern: Can produce toxins that cause food poisoning.

1) ‘Overview of Food Safety Hazards in the European Dairy Supply Chain’ by E. D. van Asselt et al.

CHEMICAL RESIDUES in the dairy industry can arise from various sources, including agricultural practices, veterinary treatments, cleaning agents, and environmental pollutants.

Monitoring and controlling chemical residues are crucial to ensure the safety and quality of dairy products.

Farm related:

• Antibiotics

• Veterinary Drugs

• Cleaning Agents and Disinfectants

• Mycotoxins

• Hormones

• Sulfonamides

Environment*:

• Dioxins and PCBs (Polychlorinated Biphenyls)

• Heavy Metals

(*ingestion through food and water from polluted environments)

Dairy Processing:

• Cleaning Agents and Disinfectants

The challenges of food health safety, hygiene and safety in the workplace have to be reconciled with environmental issues.

Factories are complex buildings with facilities, equipment and materials that may all be vectors of direct or indirect contamination. They therefore need to be cleaned and disinfected appropriately, ensuring surfaces to be

- microbiologically clean (with a well-controlled level of micro-organisms),

- chemically clean (no chemical substances deriving from production or cleaning/disinfection),

- and free from residues (and allergenic ingredients)

Choosing the most appropriate solution with Kersia means:

- ensuring that food is safe in compliance with regulations

- enforcing operator safety and equipment integrity

- making water and energy savings to optimise costs

- reducing the environmental footprint.

To achieve this, our R&D teams have developed exclusive measurement and optimisation systems that deliver significant reductions in the consumption of product, water and energy.

Tailored Solutions for the DAIRY INDUSTRY SECTOR

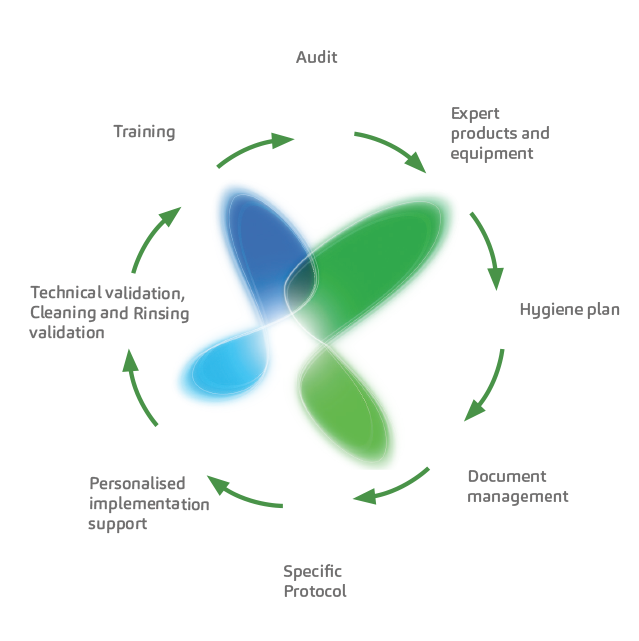

The Kersia team, from sales to scientists, work closely with businesses to advise on best practice including: the selection and application of cleaning and disinfection products, dosing and control, pathogen management, allergen management, cleaning advice, cleaning optimisation, hygiene management systems, training, audit and review for all stages in dairy production.

Case Study: Dairy Industry

Faced with problems of spore contamination which were affecting the stability of its milk, a major dairy group called upon Kersia’s expertise. A task force involving Kersia and a number of well-known microbiology equipment and diagnostics companies spent two years working to reduce contamination on the dairy group’s different production sites. The outcomes were safe finished products and major cost optimisation.

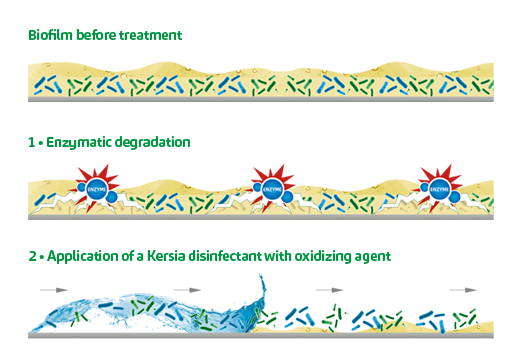

Surface Cleaning and Disinfection

Cleaning and disinfection activities in food processing plants need to follow specific sanitation programs and include dedicated and optimized solutions.

Tray & Crate Washing

Washing machines come in a variety of forms, generally being built for the cleaning of a specific type of item.

Airborne Disinfection of Surfaces

Airborne Disinfection of Surfaces

There may be a need to fog or using ULTRADIFFUSION in certain food processes to effect a reduction in airborne microorganisms.

Membrane Cleaning

Membrane technology is a proven separation method used on the molecular and ionic levels.

Clean in Place

The cleaning of complete items of plant or pipeline without dismantling or opening of the equipment, and with little or no manual involvement on the part of operator.

Conveyor Lubrication

The conveyor system on a dairy or beverage plant provides a vital link between the individual machines.

Water management

Water treatment, conservation and preservation solutions for the Food & Beverage Industry.

Support

Food & Beverage Industry

Choosing the most appropriate solution with Kersia means

As different products mean different issues, each requiring specific technologies, and each plant is unique in terms of its geographic location and its surrounding environment, Kersia’s experts offer solutions to suit the constraints of different processes. Our teams draw on their knowledge of techniques and technology to ensure regular monitoring of cleaning-disinfection protocols, via optimised hygiene product consumption and general cleaning costs, as well as controls to evaluate the parameters and the quality of hygiene practices and provide prompt warning of potential problems.

A comprehensive approach tailored and proven

KERSIA offers a hygienic method taking into account all your problems.

• OPTIMISATION

• SIMPLICITY

• EFFECTIVENESS

• REDUCTION OF GLOBAL HYGIENE COSTS

• APPROVALS

• SUPPORT

• SERVICES