In a more and more industrialized world and an increased population, the need for safe food production while taking care of our resources becomes more and more important.

One of the most vital and unique resources of the world is WATER – but at the same time this resource is threatened by scarcity due to high consumption and pollution.

This is why Kersia is committed to providing solutions.

Water treatment solution

to optimize production processes and reduce costs, energy consumption and increase possible lifetime of machinery or equipment (wear and tear of machinery through deposition, corrosion etc.)

Water conservation

to avoid negative impact on water quality (reduction of pollution, toxic components, phosphate/nitrate etc.)

Water preservation

to reduce the water consumption and to encourage the remediation of grey water

Water treatment in the food & beverage industry supporting performance of facilities

Kersia provides global and comprehensive water treatment solutions to our customers in the food and beverage industry with the main objectives to:

- Avoid scale deposition

- Avoid corrosion

- Avoid fouling

- Avoid negative impact on process performance

Food & Beverage Industry Customers from more than 120 countries worldwide trust in our solutions based on Hygiene products, Equipment and Services

THE KERSIA ADDED VALUE TO THE FOOD & BEVERAGE MARKET

Water treatment products

Tailor made product range for the Food & Beverage industry:

- Biocides

- Detergents (acids, alkaline)

- Scale Control

- Corrosion Control

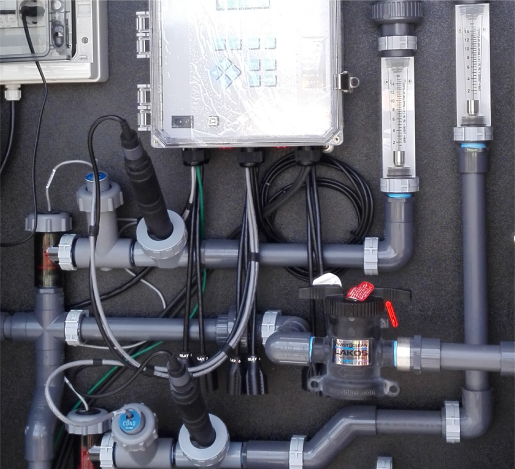

Equipment

State of the art dosing and control equipment:

- State of art dosing and control equipment

- Digital off-line monitoring capabilities leading to performance dashboard

- Fully open and transparent data management

Services

- Ability to implement global solutions including equipment proposal.

- Digital reporting and real time process performance monitoring

- Integrated solutions

Water conservation and preservation in the food & beverage industry supporting for a better ecological footprint

Water is a unique and a precious resource. This is why in recent years appearing water scarcity and pollution is becoming more and more in the focus of public attention.

Kersia aims to provide solutions to our Food & Beverage customers to conserve & preserve water by:

- the reduction of the pollution impact (e.g. use of biodegradable actives / products)

- the use of non-toxic components (no heavy metals or Ecotoxic substances)

- the decrease impact on the eco-system (nitrate and phosphate reduction)

- the solution for the remediation of grey water to increase the reuse of water

Unique and committed for global water management

Kersia, being a specialized, reliable and trustful partner in the global food and beverage industry is on top of current regulations, offering longtime expertise in hygiene and water treatment and has the ability to drive innovation. This focus on the food and beverage market combined with local and global presence makes us to the perfect partner for water management in your company – treating water while offering cost savings and improve your ecological foot print is our ambition.

Boiler optimisation & control

Boiler optimisation & control

– Optimize boiler efficiency

– Avoid corrosion

– Avoid Scale deposition

Reverse osmosis optimisation

Reverse osmosis optimisation

Treating water in order to:

– Optimize water recovery

– Avoid mineral scale

– Avoid microbial fouling

Cooling tower & cooling circuits

Cooling tower & cooling circuits

Treating water in order to:

– Avoid corrosion

– Avoid Scale deposition

– Avoid microbial fouling

– Reduce Legionella risks

Process water potabilization

Process water potabilization

Treating water in order to:

– Reduce risk of contamination

Case study : our solutions, facts & figures

Customer : Brewery 3.800.000 hl production / Asia

> Optimisation of the boiler cycling.

> Graduated plan to increase cycling at boiler in order to achieve blowdown reduction

> Implementing a documented and targeted follow-up plan with utility team

Positive impact = Savings

> Water (m3/year): 9 958

> Energy (GJ/year ): 5 836

> CO2 (tons per year): 370

TCO & KPI’s

> Savings: 119,000 $

> Products: 7,500 $

> Cycling: 50

> CBTN (*): > 95 %

(*) compliance to boiler technical reference norms

Do you know what that means for all of us?

Reducing 370 tons of CO2

≈ equivalent to 142,336 liter of fuel

≈ 1 992 000 km travelled by car

Preserving 9,958 m³ of water per year

≈ yearly Water consumption for 17 people

(people water consumption is 600 m³/y)

≈ 66,500 Showers (1 shower ≈ 150L)